Transfer Case Training 101

A peek at an important part of your HMV drivetrain, the often overlooked, transfer case.

Although this article is intended as a primer for historic military vehicle (HMV) transfer cases in general, it will focus mainly on the Dana Spicer 18 as found in most U.S. military jeeps, including the WWII Ford GPW and Willys MB, as well as the M38, M38A1, M170 and M606. The Dana Spicer 18 was also fitted to Willys and Kaiser civilian jeeps, such as the CJ2, CJ3A, CJ3B, CJ5 and CJ6, as well as used in four-wheel-drive Willys pickups, station wagons, and the FC-150 and FC-170 Forward Control vehicles. Additionally, it was used many foreign-licensed Jeep models, including those built by Mahindra Jeep in India, and Mitsubishi Jeep of Japan, as well as in early model International Scouts.

The Spicer Corporation was founded in 1904 by Clarence Spicer, who soon partnered with Charles Dana. The Dana Spicer Corporation manufactured automotive power train and chassis components through the most of the 20th century.

The Dana 18 is one of the simplest and easiest transfer cases to rebuild and repair. In most cases no special tools except a good pair of snap ring pliers are required. One should have, or make, a brass rod to drive out the intermediate gear shaft and other such tasks; never hit the shaft or other parts directly with a hammer or they may chip. The intermediate shaft drives out through the REAR of the case. The shaft is slightly smaller at the front, and trying to drive it out through the front may crack the case. Check the case for cracks around the intermediate shaft bore. If there are cracks, it usually indicates that someone did try to drive the shaft out through the front.

Designed in 1940, the Dana Spicer Model 18 was in production for 30 years. Even after it was updated to the Model 20, it remained basically the same, making it one of the most successful vehicular components ever made. Even today, all of its internal parts are still being manufactured and are readily found almost anywhere in the world. When viewed as a whole, the design is somewhat elegant for a piece of machinery, almost having the same kind of 1930s look of a Douglas DC-3 airplane. Like that famous aircraft, it was massively overbuilt and astonishingly durable.

Throughout its years of production, the only significant changes to the Dana 18 were increasing the size of the intermediate gear shaft, which was originally 3/4” in WWII and early CJ2 jeeps, then was enlarged to 1-1/8”, and finally to 1-1/4”. The main reason for the increase in size was to provide more surface for the intermediate gear’s roller bearings.

But, to begin at the beginning, what is a transfer case?”

I bought my first jeep, an M38, when I was 16, back in the day when jeeps were so rare that their drivers waved and smiled at each other out the road. I had taken it for a lube job, and the gas station mechanic — who couldn’t understand why anyone would want such a vehicle — told me a transfer case was, “another transmission, and something else to go wrong.”

One could indeed say a transfer case is another transmission in the sense that it transmits engine power to the driving wheels. A conventional manual transmission in a rear-wheel-drive vehicle transmits engine power to the rear axle only, while giving the driver a choice of gear ratios, usually three or four in forward and one in reverse. However, for an all-wheel-drive vehicle a transfer case is needed to also transmit (or transfer) engine power to the front axle. It also acts as a power divider, which is why the front drive shaft on most all-wheel-drive vehicles is smaller in diameter than the rear. On many small vehicles, such as jeeps, the transfer case is bolted to the rear of the transmission. On most larger vehicles, the transfer case is a separate unit mounted behind the transmission and coupled to it by a short drive shaft.

A single-speed transfer case, such as those used in 1/2-ton WWII Dodges and many 3/4-ton Dodge carryalls, is basically a directional gear box that transfers power from the engine after it leaves the main transmission to all the vehicle’s wheels. It also usually gives the vehicle’s operator a choice of powering only the rear wheels, or both the rear and front. If the main transmission is a 4-speed, there are still only four gear ratios forward and one in reverse, either in or out of four-wheel-drive.

One might ask, “Wouldn’t it be better for a tactical military vehicle to always be in all-wheel-drive?” The answer, yes, but the problem with powering a vehicle’s front and rear wheels on a full-time basis is that they turn at different speeds. For example, when going around a corner, the outside wheels have to travel farther — make more revolutions — than the inside wheels, which is why drive axles have differentials. This works fine if only one axle is powered: the differential can compensate. But, if two or more axles are powered together, and especially if one is a steering axle, they fight each other. Why? Because each of the vehicle’s wheels is turning at a different speed. This also happens to some extent while traveling in a straight line, since the driver is always making corrections to keep the vehicle on course. In addition, tires are seldom precisely the same size, and almost never the same size if of different ages, states of wear, or if made by different companies. Tire size may also differ due to unequal inflation. A larger tire rolls more slowly (makes less revolutions) to travel the same distance as a smaller tire. This isn’t much of a problem for an all-wheel-drive vehicle as long as the tires can slip a little, such as in mud, gravel, dirt or snow. However, if the vehicle is used on dry pavement it’s difficult for the tires to slip, and this puts a strain on the whole drive system from the transmission and transfer case to the drive shafts, differentials and axles. It also puts more wear on the tires, and doesn’t improve gas mileage either. A modern full-time all-wheel-drive system has what amounts to a differential built into the transfer case, which compensates for these different wheel speeds, but for most vintage HMVs and civilian 4x4s never engage front-wheel-drive on hard dry surfaces where the tires can’t easily slip.

Early M35 type trucks had an automatic-engagement transfer case, and we’ll get to those later. But on most WWII and smaller M-series vehicles such as jeeps and MUTTs, the driver has a choice of manually selecting either rear wheel drive or all-wheel-drive.

With a single-speed transfer case there are only the gear ratios available from the main transmission, either in or out of all-wheel-drive. Most of the time this is sufficient: WWII Dodges had a very low first gear, which usually gave them enough power to crawl through mud or climb steep grades. Still, there were times when an even lower gear was needed, such as when the trucks were heavily loaded or towing trailers and had to get through swampy terrain, across a river, or up a mountain.

There are several ways to increase a vehicle’s useful power: it can be given a bigger engine… but then it may need a stronger transmission and heavier axles. It could be given a lower axle gear ratio… but that will decrease the vehicle’s top speed. It could be given a transmission with an extra-low first gear… but most of the time, a gear that low would only be needed in all-wheel-drive. None of these options were favorable during WWII when many military vehicles were being built as fast as possible using already existing components. So, why not put a lower gear into the transfer case? Then, if the main transmission is a 3-speed, as in most jeeps, the vehicle will have six gear ratios forward and two in reverse. A 4-speed truck, like a Dodge WC, now has eight gear ratios forward plus two in reverse, while a CCKW or DUKW with a 5-speed transmission has ten gear ratios forward plus two in reverse.

Most 2-speed transfer cases, such as the Dana 18 and other units used in larger vehicles, have a lockout so the lower gear ratio can only be used when the vehicle is in all-wheel-drive. This is to prevent excessive torque loads on the rear axle(s). As with most safety features, this can be bypassed (very simply in the Dana 18), but there is little practical use in doing so. Furthermore, bypassing runs the risk of overloading and breaking the rear axle(s).

Transfer cases can be grouped into two basic types: those that mount on the main transmission, as on most jeeps, and those that are separate units, such as on M37s, M715s, and M35s. Transfer cases may also be subdivided into gear-drive types (as in jeeps and most common HMVs) and chain-drive models. While the latter are often used in modern trucks and SUVs, they were also used on many old-time, large, all-wheel-drive trucks such as those made by Oshkosh, Coleman, Mack, and FWD.

By now, one should understand the basics of what transfer cases are and what they do. As with any component on an HMV, if there is major work to perform and one wants to know how to service it right, get a manual. Here are some answers to often-asked transfer case questions, and various trouble-shooting hints:

Why is a vehicle’s parking brake usually on the transfer case and not on the main transmission? Since most two-speed transfer cases have a neutral position, a parking brake on the main transmission could not keep the vehicle from rolling if the transfer case was shifted to neutral.

Why does the speedometer usually drive off the transfer case and not the main transmission? If it drove from the main transmission, it wouldn’t read correctly when the transfer case was in low-range.

Why should the transfer case and the transmission both be in neutral when towing a vehicle? In some vehicles, the rear bearing in the main transmission doesn’t get oiled if towed with the transfer case in gear, but you should consult a manual to be sure of the correct procedure before beginning a tow.

Is it okay to shift into four-wheel-drive with front axle locking hubs unlocked? It’s fairly harmless for a little while and as long as there aren’t heavy torque loads (which only the rear axle would be subjected to) but there would usually be no need to operate a vehicle this way. An exception might be a vehicle in a parade operating on pavement when using low range in the transfer case would allow very slow speed. Always make sure both hubs are fully locked or fully unlocked. It’s not going to be an instant disaster, but never drive a vehicle with one hub “in” and one hub “out.” And check them every so often, because inquisitive parking lot fingers will sometimes turn them. Incidentally, it’s usually easier to lock the hubs before shifting into all-wheel-drive. If the hubs won’t lock, just move the vehicle an inch or so. The hubs have gear teeth inside and sometimes those teeth don’t mesh at first. If the vehicle has been operated in all-wheel-drive, and the hubs won’t unlock, just back up a little. This relieves built-up tension on the axles and drive train. Unless a hub has been damaged, only use your fingers to turn their mechanisms. Don’t try to force them with wrenches or pliers.

Yet another question, and one that’s asked more frequently these days by younger HMV enthusiasts, is about transfer case noise. Most of us over 50, who have had experience with older jeeps or other all-wheel-drive vehicles, know that transfer cases whine. This is due to the design where three gears are running together. (Chain-drive transfer cases have their own sounds.) But a whine — not a scream — is normal, and there’s usually nothing wrong. The sound will generally rise in pitch and volume as the speed of the vehicle increases and the transfer case oil warms up and thins out. Loose transfer case control levers will transmit the whine and make it sound louder. Grasp the levers as you’re driving and see if this quiets things down. If so, figure out how to make the levers tighter. On jeeps or other vehicles with Dana 18 transfer cases, the anti-rattlers or lever springs are sometimes broken or missing, so check and replace if necessary. One HMVer solved his jeep’s noise problem by simply stuffing a piece of foam rubber between the levers. One can try replacing the control lever bushings on other vehicles. Loose linkage rods, bell-cranks, and worn clevis pins will also amplify transfer case whine. Also check the transmission hump or cover on the vehicle’s body to see if it’s loose, which may amplify whine. Shift levers that touch the transmission hump or cover, sometimes unseen under the dust boot or bellows, will likewise amplify noise. New engine, transmission and transfer case mounts may lessen the noise, but there’s really not a lot one can do... those three gears running together just naturally give off a whine.

Since military jeeps and most early civilian models were intended mainly for off-road use, this whine wasn’t considered objectionable: however, as recreational off-roading became popular and the vehicles were also used more on the highway, the Dana Model 20 eliminated most of the noise by moving the rear drive shaft output from the right to the center. Besides being touted as a “silent transfer case,” it raised the rear output shaft above the level of oil inside and eliminated a potential leak source.

How strong are transfer cases? In most applications, the Dana 18, if treated well, will outlast the transmission… often two or three of them in early jeeps. And, if treated well, they are capable of handling much larger engines than those of most stock jeeps.

Which is better, a single control lever or the two “sticks?” Most serious off-roaders prefer twin sticks. The best single lever control I ever saw was on a ’72 Scout II. The worst was on a ’65 Jeep Gladiator. One can convert most single stick models to twin-sticks, and there are kits available.

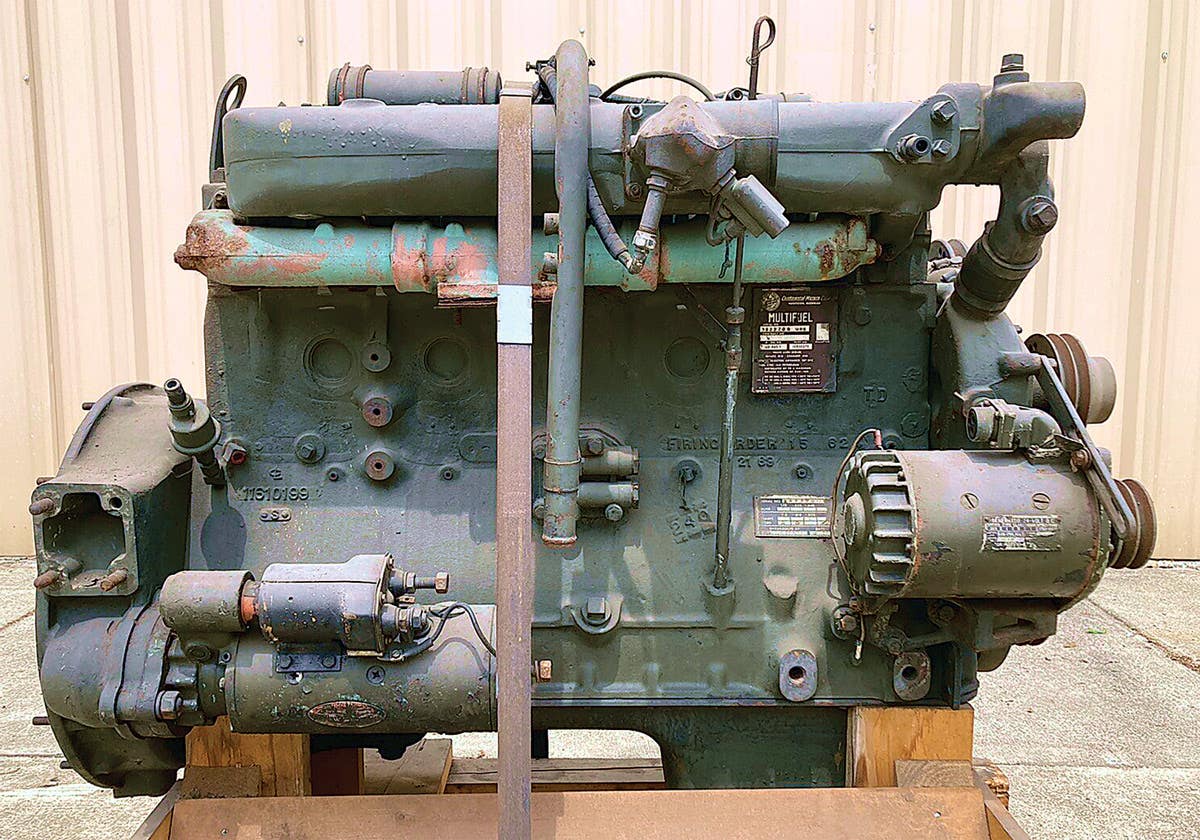

What about automatic transfer cases, meaning those that engage the front axle without the driver’s effort or consent? These are commonly found on early M35s, both gas and multifuel. There is no computer involved; they are based on a Sprag clutch principle. When the rear wheels start turning faster than the front wheels, such as when spinning in mud or snow, the clutch engages front axle drive. Then, as soon as all the wheels are turning about the same speed, the clutch disengages and only the rear wheels are powered. There are a few situations where one might not want this to happen, but these transfer cases are long-lived and pretty much trouble-free, provided they’re lubed and serviced properly. They are sometimes prone to clutch wind-up, which may unexpectedly spin a front wheel if it’s jacked off the ground. The best way to prevent this is to never let the vehicle roll backward with the transmission in a forward gear.

The GMC M135/M211 and variants used a single-speed transfer case and the low range was in the automatic transmission. This setup worked well as long as things were kept properly adjusted.

One of the biggest little problems one may encounter with the Dana 18 is with the output shafts to the front and rear axles. They are located below the oil level, which puts more strain on the oil seals. And because no rotating seal is perfect, some oil will usually leak out. It’s usually not serious on the front drive shaft, but leaking oil from the rear output often goes on the parking brake, which then may not hold. The seal isn’t hard to replace, but one should also check that the sealing surface on the companion flange doesn’t have a groove worn into it. If so, one should replace the flange or get a “Speedy Sleeve.” Putting silicone sealant on the output shaft splines before installing the companion flange will also eliminate a potential leak. One should check the flange nut for tightness every once in a while. A loose flange will wobble and wear out the seal.

Most of the above tips also apply to other types and sizes of transfer cases. Always read your vehicle’s manual, but most common HMVs use the same oil in their transfer case as in the transmission and differentials. One exception is the Dodge M880, which uses the same oil in the transfer case as it uses in the engine.

If your vehicle’s transfer case is attached to the main transmission, check the bolts for tightness, from time to time. Likewise, check the mountings on separately mounted transfer cases, as on M37s and M715s.

Never try to force the shift levers either into or out of gear. If they seem to be stuck — and you know, for a fact, they’re not just rusted or packed with dirt — simply move the vehicle a little and they should slip into place. If the vehicle itself is stuck and can’t be moved, put the main transmission in gear with the engine running and gently let up on the clutch while keeping a hand on the transfer case lever. It should slip into gear. A transfer case that repeatedly jumps out of gear generally needs a rebuild, assuming the shifting mechanism is properly adjusted and the detents are working.

The Dana 18, besides being one of the best transfer cases ever made, is also one of the simplest and easiest to rebuild and repair at home. There are many web sites devoted to this job, most with good (though sometimes conflicting) advice, so there’s no use in repeating it in this article; but here are a few tips based on my experiences:

In most cases, no special tools except a pair of snap ring pliers are required. You should have, or make, a brass rod (I use a piece of a boat propeller shaft) to drive out the intermediate gear shaft and other such tasks. Never hit the shaft or other parts directly with a hammer. They may chip.

An easy way to install the intermediate gear, shaft and bearings in a Dana 18 is to make a dummy shaft from a piece of wooden dowel. I found an old hardwood chair leg that was the perfect size. Use bearing assembly grease to hold the rollers in place. If one uses wheel bearing grease it may not dissolve in the gear oil and could clog the oil hole for the intermediate shaft bearings. Vaseline will also work, and will stick better if put in a fridge overnight before using. Replacing a Dana 18’s intermediate shaft and bearings can be done with the transfer case in a vehicle, but it’s usually a test of one’s patience, dexterity, and threshold of rage. The parking brake assembly must be removed before removing or installing an intermediate shaft.

The intermediate shaft drives out through the REAR of the case! The shaft is slightly smaller at the front, so trying to drive it out through the front may crack the case.

Check the case for cracks around the intermediate shaft bore. If there are cracks, it usually indicates that someone did try to drive the shaft out through the front. In “civilized” conditions, such cracks are not considered repairable, and the usual advice is to get another case. Under less civilized conditions, one can try welding or brazing.

Check the intermediate shaft for wear or galling. Most shafts — especially the 3/4” shafts — on vehicles that are driven frequently will require replacing. While there are replacement kits available that include a new shaft, bearings, and bushings, many such kits (including some with “USA”-stamped shafts) have soft shafts that will quickly wear out, so buy these kits from a reputable source.

One way to tell if a shaft is soft is to take a sharp punch and a medium-sized hammer, and try to made a dimple at one end of the shaft (the section that mounts in the case, not the bearing surface). Tap the punch smartly with the hammer, once. A good shaft won’t dimple.

A handy special tool for working on a Dana 18 is a wedge to separate the output shaft bearing. Some people have made such a wedge from a cheap hatchet head. Though not absolutely necessary, it makes the job easier.

One can upgrade an early Dana 18 to accommodate larger intermediate shafts, though in most cases there is no need to go above 1 1/8”.

Don’t use a magnet to handle or fish out the roller bearings. They will become magnetized themselves. This will cause them to skid instead of rolling. Don’t mix old and new rollers — unless you’re out in the wilds and have to — because the worn rollers won’t carry their share of the load.

While gasket sets are readily available, one can easily make their own. I use old-fashioned Permatex, not silicone. Gasket paper is best, but I made some gaskets out of manila folders 10 years ago and they’re still fine.

If your transfer case doesn’t already have one, get a magnetic oil drain plug.

A constant rhythmic clicking sound in a transfer case often indicates a chipped or broken gear tooth. Check the gears immediately! A chipped or broken tooth will quickly damage the other gear teeth and could result in major damage to the transfer case itself.

That’s about it for basic transfer case training. There’s a lot of helpful information on the Web, and, as with your HMV itself, get the service manual!