Changing Your MV’s Oil

by Steve Turchet Unless you have already owned a vehicle that was built before 1970, you may be surprised to find that your “new” MV requires a lot more service…

by Steve Turchet

Unless you have already owned a vehicle that was built before 1970, you may be surprised to find that your “new” MV requires a lot more service and maintenance than a modern car or SUV. You will probably also find that even doing an oil change on a vintage MV is beyond the capabilities of many quickie-lube joints and their (usually) teen or twenty-something staff. Beware that even if such a place actually attempts to service your WWII jeep, they probably won’t do a proper or complete job. In other words, when it comes to taking care of your vintage MV and keeping it “MC” (Mission-Capable), you will probably have to do it yourself, that is, if you want it done right.

WHAT YOU NEED: THE BASICS

The first thing you should get is a service manual for your vehicle. Such manuals can usually be ordered from companies that advertise in this magazine, and/or may be found on the Web.

Of course, you will also need basic mechanical skills and a basic tool set. I can’t help you much with the skills —though you will quickly learn them as you go along. But, as I’ve suggested in previous articles, a good basic tool set for working on most common U.S. hobbyist MVs consists of the following items:

— Set of combination wrenches, 5/16” to 13/16”

— 3/8” drive socket set, 3/8” to 13/16”, including a spark plug socket (make sure the latter fits your waterproof plugs!)

— 3/8” ratchet wrench

— 3/8” “breaker-bar”

— 3/8” socket extension 3-4 inches long

— 3/8” socket extension 6-8 inches long

— Pair of slip-joint pliers

— Pair of Channel-lock type pliers

— Pair of wire-cutters or lineman’s pliers

— Pair of Vise-Grips

— 8-inch Crescent wrench

— 10- or 12-inch Crescent wrench

— Pipe wrench that opens farther than your largest Crescent wrench

— Three or four good screwdrivers, including a Phillips-head. (A good “four-in-one” screwdriver is also quite handy)

— Medium-sized ball-peen hammer

— Feeler gauge for setting spark plugs and ignition points

— Ignition points file (and/or emery cloth)

— Pair of very small Channel-lock pliers for working on things like the distributor

—Small chisel

— Probe-type electrical tester—one that’s right for your MV’s voltage

Not only is this a good basic tool set for working on your vehicle at home, but it should also be carried in your MV at all times. In addition, if you’re going to be performing your own vehicle service at home, you will need a grease gun and grease to do lube jobs, and an oil drain pan for changing the engine oil.

You will also need a gear oil pump and gear oil for changing and/or topping-off your vehicle’s transmission, transfer case, axle differentials, steering box, and maybe the front axle steering knuckle joints and the winch gear case as well.

In these days of environmental concerns, you will probably also need suitable containers in which to properly dispose of used oil. In many urban and suburban areas such containers are available free at auto-mart type stores or other places that sell engine oil. If not, one can usually find a place that accepts used oil by looking in a phone book or doing a Web search.

You will also need a large supply of rags, and you will probably find that no matter how large a supply you have it will never be large enough! Red cotton mechanics rags are the best, old cotton T-shirts will also work, but polyester fabrics are useless.

DON’T FORGET OIL AND A FILTER

This article assumes that you have just purchased a mostly complete and drivable vehicle and that you intend to keep driving it for awhile. Now it’s time to get dirty—and you will get dirty—by performing an engine oil change.

What else will you need in addition to the tools and items suggested above? Obviously, since you’re changing the engine oil, you’ll need enough new oil to refill the engine. If you have a manual it should tell you how much oil you’ll need. If you don’t have a manual, you’ll just have to read the dipstick when you’re refilling the crankcase, and keep in mind that you’ll usually need one or two quarts more for the oil filter.

Ah, the oil filter! You will know that you’re really part of the military vehicle hobby as soon as you discover that you can’t just bop into your friendly neighborhood monster-mart and expect to get anything except a blank look or a laugh when asking for an oil filter for a 1944 Willys Jeep, a 1942 Dodge WC, or a 1958 Dodge M37 ( among many other common MV hobby vehicles).

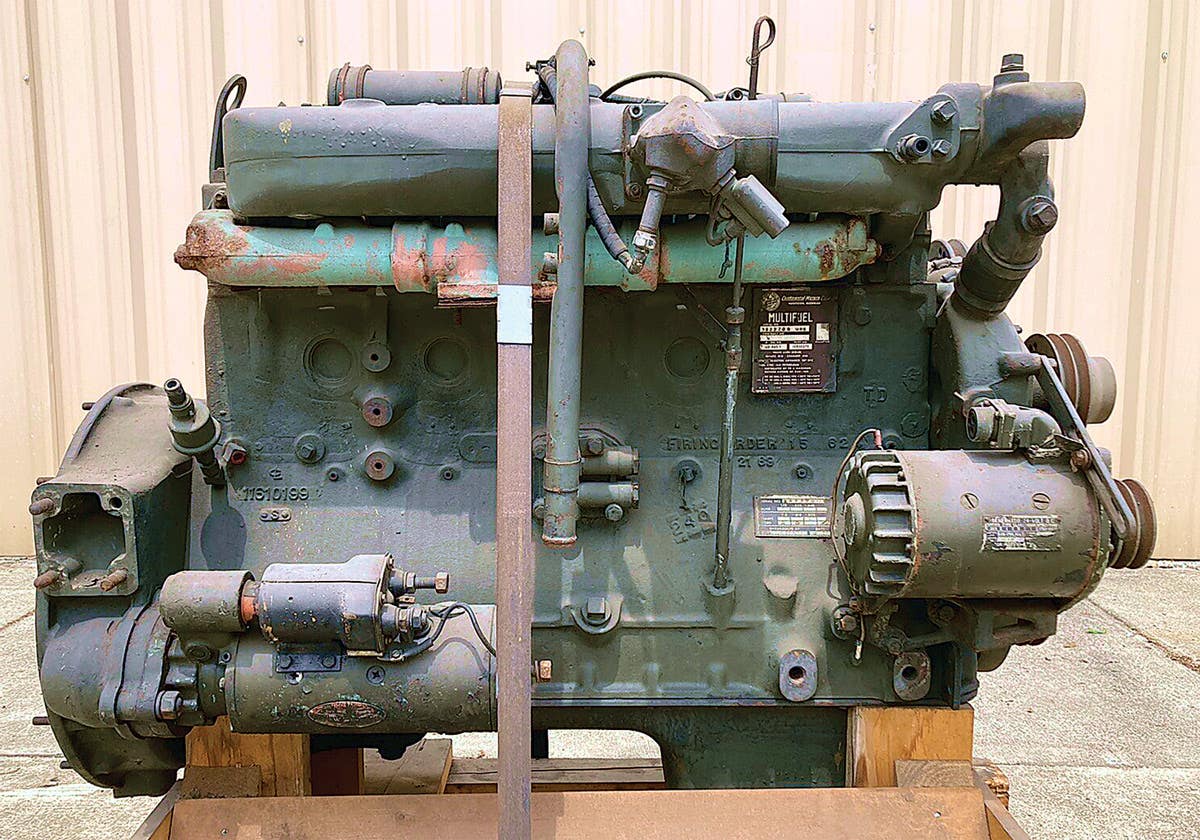

Prior to the M151 MUTT and the Kaiser M715 which used “modern” full-flow spin-on type oil filters, most U.S. MVs used a bypass type oil filter with replaceable elements. The “element” is the part of the filter that does the filtering.

What is the difference between a bypass oil filter and a full-flow filter? Their names illustrate how they function, and the bypass type does exactly what its name implies—a portion of the engine oil being circulated by the oil pump bypasses the main lubrication system and is routed through the filter where particles of metal and dirt are trapped in the filter element. There is a point at which the oil has a choice of which way to go. Some of it bypasses into the filter while most of it goes straight through the engine’s lubricating system. On the other hand, the full-flow type filters all the engine oil, usually right after it leaves the oil pump under pressure.

Is one type better than the other? We’ve just learned that the full-flow type filters all of the engine oil each time it makes a circuit through the lubricating system. Since all the oil is filtered before it gets pumped to the bearings, this must be the best filter, right? Not necessarily.

Because all the oil must pass through a full-flow filter each time it goes around, the filter element cannot be restrictive—cannot slow down the flow of oil—or it would starve the engine of lubrication. Therefore, the full-flow element cannot be made as fine as a bypass type.

Since a bypass type filters only a part of the oil each time it makes a circuit through the engine, it can be made to filter very small particles. While some bypass filter elements for common MVs may still be found at commercial truck and/or equipment supply dealers, they usually have to be referenced by a part number rather than vehicle type—asking for an oil filter for a 1958 Dodge M37 still won’t get you anything but a blank look or a laugh. You will need the filter element manufacturer’s number, and about the only sure way to get it is off the old element you’ll be taking out. It’s best to take the old element with you to the store ... messy as that may be, and we’ll get to messy soon.

Of course, you can usually order the correct filter element from a company that advertises in this magazine, but that is assuming your vehicle has the correct filter. So again, until you know your vehicle, the best way to be sure you’re getting the correct oil filter element is to take out the old one. Unfortunately, it’s possible that there either isn’t an element in your filter case, or that it’s not the correct one, but we’ll also get to that soon.

While there are many types of by-pass oil filters used on most common U.S. military vehicles, they can be roughly grouped into two categories. The first are the pre-M-series vehicles. Although in the latter part of WWII there was an attempt to standardize oil filters, most vehicles still used different filters. For example, an MB or GPW jeep used a different filter than a Dodge WC, which in turn used a different filter than a G.M.C. CCKW.

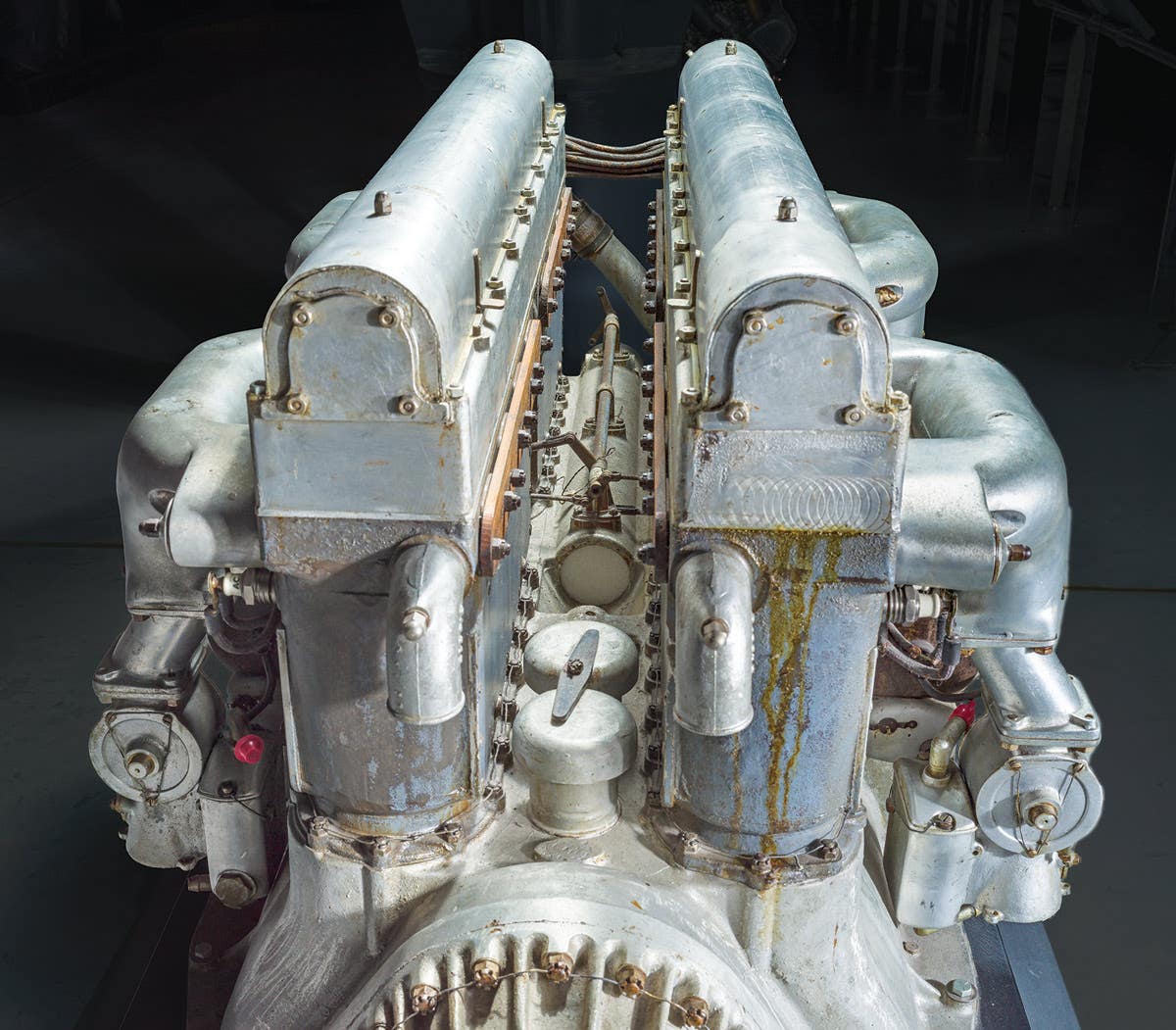

After WWII, and with the advent of M-series vehicles, most oil filters were standardized into the Military Standard Junior and the Military Standard Senior. The Junior evolved from the filters used on most WWII Dodges and some Chevrolet G-506 trucks, while the Senior evolved from the filters used on most GMC CCKWs. For large engines, including some diesels such as the GM 6-71 which was widely used in landing craft such as the LCVP, LCM, and LCT, the filters were often doubled or tripled. Elements for either the Military Standard Junior or the Military Standard Senior are still available from many of today’s commercial suppliers, but, again, you will need the manufacturer’s part number.

By the way, if you have an M151 or M715 with a full-flow spin-on oil filter, you will need an oil filter wrench in addition to the other tools and items already suggested. You will also need the filter manufacturer’s number to get a replacement, though replacements for these can usually be found at monster-marts and most auto parts stores.

Okay, let’s get messy!

IT’S DRAIN TIME

Your engine should be well warmed-up so that all the gunk and goo is suspended in the oil and not left laying in the bottom of the pan. In average T-shirt weather, a drive of about five miles should be enough. In any case, the engine oil pan should feel hot to the touch. Drain the oil into a suitable container by removing the oil pan drain plug.

While this is happening, open the filter case by unscrewing the large bolt on top. On some filters this bolt is removable from the cover, but on others it’s not, so don’t try to pull it out if it won’t come out. Then remove the cover. Oil shouldn’t pour out all over the place but I can’t guarantee that it won’t, so be prepared with rags. If the cover is stuck, tap it gently upward with a wrench or small hammer, but don’t jam in something like a screwdriver and pry or you might bend it and then it won’t seal.

For a minimum of mess, don’t remove the filter element yet. Instead, get a coffee can or other suitable container (and one that’s obviously large enough to hold all the oil in the filter) remove the drain plug from the bottom of the filter case and let the oil drain into the can. Wait a while so that most of the oil drains out of the element.

On the other hand, if you want a mess, just yank the element out right now and you’ll have it in abundance! Some Military Standard Junior or WWII type filters don’t have drain plugs, so you’ll have a mess anyhow. By the way, did you consider where you were going to put the dripping element before you pulled it out? Incidentally, if you don’t loosen or remove the cover before you open the filter drain plug, you will usually have an air-lock inside the filter case and the oil will take much longer to drain out.

Because the bottom of the filter case isn’t flat there will always be a little oil left inside, but when you’ve drained all you can, remove the element from the case. If it’s the correct element, it should fit tightly around the center tube, and some pulling and twisting may be required to remove it. Then, thoroughly clean the inside of the case and get all the guck out of the bottom. On filters that don’t have drain plugs, this will be a messy job and you’ll have to use lots of rags and/or paper towels to sop out all the oil. If you’re using paper towels, be careful they don’t come apart and leave wads of paper in the filter case.

Some filters may have a tension spring under the cover bolt, while others may have a spring in the bottom of the case. A few may even have springs top and bottom, but the important thing is that your new element must seal tightly, top and bottom, around the center tube. Assuming your old element was the correct one, it’s easy to compare the old and new to see if they’re the same. The correct element for this type of filter not only seals tightly top and bottom around the center tube, but it also fills the filter case.

You may find that your vehicle’s previous owner installed some sort of “universal replacement” element instead of the correct one. This is will be obvious if the element seems much smaller than it should be for the size of the case...common sense would dictate that there would be no reason to have a large case with a small element inside. If you do find this, then using the old element’s part number will only get you another incorrect element, so you’ll have to do some research to find the right one, such as contacting companies that advertise in this magazine or asking for help on a military vehicle website.

After you’ve cleaned the filter case, prepare to install the new element. If there are any additional sealing washers used, make sure they’re in place. Then put some new oil on the element’s seals, top and bottom, and slip it down over the center tube until it’s fully seated. Oiling the tube itself may be helpful to slide the element down. Install the filter case drain plug.

Now prime the filter by filling it with new engine oil. This is important! If you don’t prime the filter, it will take longer for the engine to build up oil pressure when you start it. Priming a filter takes time because the oil has to soak into the element. Be patient and keep adding oil until the case remains full. You may not be able to fill the case all the way to the top because oil will run back into the engine through the outlet, but fill it until the level remains constant.

Now replace the fiber washer under the cover’s top bolt, if such a washer is used. If your new element didn’t come with a new washer, it’s okay to reuse the old one if it seems in good shape. Otherwise you’ll have to do some improvising to make a new one. Rubber won’t work, being too soft, but a visit to a good auto supply (take the old washer along, of course) should get you something—maybe a fiber or nylon washer for an oil pan drain plug. Coat the washer with new engine oil before installing it.

Now, install the new cover gasket. Don’t use gasket sealer on it—coat both sides with new engine oil instead— and never use silicone!Silicone gasket sealer is great stuff when used properly, but it can also get into oil passages and clog things up, which can cause a rod or main bearing to burn out. Sometimes you can reuse the old gasket and keep the new one for a spare... preserve it with WD-40 in a baggie. If for some reason you find you have to make this gasket yourself, it’s better to use thick gasket paper, because most rubber, such as a piece of old inner-tube, will soon swell up, get flabby and leak.

Tighten the center bolt firmly, but don’t over-tighten or you might distort the filter cover. If in doubt as to how tight is tight, it’s better to leave it a little looser than you might think is necessary, then tighten it a bit more if the gasket leaks under pressure when you start the engine.

Now, replace the engine’s oil pan plug and fill the pan with new oil. Check the dipstick to be sure it’s full. Then start the engine but don’t rev it up, and wait for oil pressure to show on the gauge. As soon as it does, leave the engine idling, check for leaks at the filter, and tighten the cover bolt a bit more if necessary. Also check to make sure there are no other leaks anywhere else, such as around the oil pan drain plug. Finally, shut off the engine, wait a few minutes, then check the oil level on the dipstick again... you may find that you have to add a little more oil.

Some people believe it’s good to keep an extra quart of oil in an engine—“a quart high.” While in most cases this can’t hurt anything, having the crankcase oil level too high may cause the oil to be churned into foam by the crankshaft. So, until you’re really familiar with your vehicle, it’s probably safest to keep to the correct oil level as indicated by the dipstick.

WHAT ABOUT SPIN-ON FILTERS?

If you have an M151, M715, or another MV with a spin-on filter, here is the procedure for changing that. First, you need a good-quality oil filter wrench. There are several types, but I prefer the steel band model instead of those that look like big sockets. Don’t bother with wrenches offered in bargain bins because they usually can’t handle filters that are stuck on tight and will only bend or break. Plan on spending around ten bucks for a good quality wrench.

Most people, even otherwise skilled mechanics, install spin-on filters too tightly. This can make them very difficult to remove, especially if they’re been on a for long time. If this is the case with your vehicle, you’ll often find that the socket type wrenches will slip, and sometimes even the band-type wrenches will crush the filter’s case. A last and messy resort is to take something like a long, strong Phillips-head screwdriver, pound it through both sides of the filter case like a joke arrow through somebody’s head, and twist the filter off using the screwdriver for leverage. Remember that it unscrews counterclockwise just like a nut or bolt. If the filter is mounted to an aluminum housing, use common sense in trying to remove it so you don’t break the mount.

After the filter is off, wipe the mount with a clean rag, being careful not to push dirt inside or leave scraps of rag behind. Just as with bypass type filters, you should prime your spin-on so you’ll have engine oil pressure as soon as possible after start up. For spin-ons that mount vertically (open end up) this is easy; but just as with bypass filters, priming a spin-on takes time because the new oil has to soak into the element. With filters that mount at an angle or horizontally, you won’t be able to prime them all the way, and there will be some leakage when you screw them on, but even a little priming is better than none.

After the filter has been primed, smear some new engine oil on the gasket and screw the filter onto the mount. Just about every spin-on filter has the words, “HAND TIGHTEN ONLY” on it, and usually, “1/2 turn after the filter contacts the mounting base.” But most of us can’t resist adding another turn with a filter wrench. Normally this practice is harmless and only makes it a little harder to remove the filter next time you change the oil, but excessive over-tightening can strip the filter threads or even damage the mount. The filter gasket is designed to swell up a little, so the filter will always be tighter when you go to remove it again, so that extra turn we tend to give it really isn’t necessary.

A better method is to tighten the filter by hand only, then check for leaks or drips after engine startup. Keep in mind that if you’ve primed the filter, those drips may only be excess oil and not leaks. Excess oil will stop dripping after awhile but a leak will continue.

After you’ve installed the filter, replace the engine’s oil pan plug and fill the pan with new oil. Start the engine and wait for pressure to show on the gauge. Then leave the engine idling while you check for leaks. Then shut the engine off and check the dipstick.

Congratulations! You have just changed your MV’s engine oil and filter and probably learned a lot about your vehicle in the process.